Post by aerofoto - HJG Admin on Apr 23, 2007 6:47:21 GMT

Despite lacking a history of commercial aviation successes like those of its Douglas rival, Boeing benefitted from huge military/government investment (USAF C135 contract) and was advantaged by ability to offer more competitive aircraft terms. Whilst Douglas developed DC8's to meet a variety of operational requirements, it was reluctant to compromise its basic aircraft design during early production years unlike Boeing who tailored B707's to the needs of specific customers almost from the very beginning of its jetliner program. These factors played a significant role in boosting the appeal of B707 and ensured Boeing's success among airlines of the world.

B707-320 & -420 became highly successful long range intercontinental jetliners but were quickly superseded by advent of P&W fanjet engine technology offering more power, better fuel economy, and greater environmental acceptability. These benefits promoted development of the definitive B707 series marketed as B707-320B & B707-320C (competing with DC8-50 & -62). These new versions retained the long B707-320/420 fuselage, and basic wing design ...though modified with low-drag curved tips which also increased overall wingspan by 3ft 3.5in. The B707-120B & B720-020B leading edge extension/wing glove was never incorporated into the wing design of these aircraft but flap systems were redesigned and varied slightly between both versions. B707-320B & -320C were capable of higher operating weights, longer range, and far superior performance than any of their type predecessors.

B707-320B first flew on January 31 1962 and was awarded FAA certification on May 31 1962. Deliveries commenced to Pan American from April 12 1962. All B707-320B's featured the standard extended tail. Very early production aircraft also retained the lower rear fuselage ventral fin, and were powered by original P&W fanjet series engines with small sucker doors located near the center of each engine inlet casing ...similar to those of B707-120B & B720-020B models and early type nose gear doors. Early B707-320B's aircraft were also equipped with half span slotted leading edge flaps and a revised trailing edge flap system featuring a unique Flap 17 detent.

Later production versions, and by far the majority of B707-320B aircraft built, were designated B707-320B ADVANCED models. These aircraft had slightly more powerful P&W fanjet series engines with larger sucker doors (further improving air-flow through each engine) relocated near the leading edge of each engine inlet casing and redesigned nose gear doors. B707-320B ADVANCED aircraft were also equipped with full span slotted leading edge flaps and a further redesigned trailing edge flap system featuring a standard Flap 14 detent. These modifications promoted corresponding performance improvements and slight MTOW increases. B707-320B ADVANCED aircraft also dispensed with the lower rear fuselage ventral fin. Some early prodution B707-320B's were later upgraded to ADVANCED aircraft standard.

A very small number of B707-320B's were produced with a forward fuselage maindeck cargo door but lacked reinforced flooring of the convertible B707-320C. These became reduced MTOW combi type aircraft intended for flexible or mixed PAX/freight operations ...designated B707-320B SCD. This version first flew on May 15 1964 and 13 months after first flight of B707-320C. Only 4 airframes were ever produced. All were delivered to Northwest Airlines.

American Airlines B707-323B ADVANCED aircraft were equipped with only 2 rather than 3 turbocompressors of most other -320B/C & -420 versions and featured a different shaped # 4 engine pylon. A total of 174 B707-320B airframes were produced by Boeing. The last of the type being delivered to BOAC on April 17 1971. During the 1980's a small number of B707-320B's were converted to pure freighters. Most of these aircraft were eventually Husk-Kitted to meet Stage 2 & 3 FAA/ICAO noise regulations of the 1980's and 90's. All B707-320B's had a fuselage length of 152ft 11in, wingspan of 145ft 8.5in, and capacity for 121-141 PAX depending on aircraft/airline configuration. These aircraft were powered by P&W JT3D-1, JT3D-3, or JT3D-3B fanjet engines (depending on airline selection) rated at 17,000-18,000lb/st e/a, and had a MTOW of 331,000lb ...later increased to 335,000lb, and range of some 5,250nm depending on payload and reserves.

Further enhancement of the basic B707-320B resulted in the ultimate B707 aircraft ...designated B707-320C. Although visually identical to the preceeding B707-320B ADVANCED this version was developed as a longer ranging and higher MTOW convertible aircraft for flexible or mixed PAX/freight operations (competing with both DC8-50F & -62CF/F). The B707-320C was equipped with an 11ft 2in X 7ft 7in port side forward fuselage maindeck cargo door, in addition to standard underfloor baggage/freight hatches located on the lower starboard fuselage, and had a strengthened undercarriage for higher operating weights. B707-320C first flew on February 11 1963 and was awarded FAA certification on April 30 1963. Deliveries commenced to Pan American from May 2 1963. All were delivered with the standard extended tail. The lower rear fuselage ventral fin having become completly redundant from the B707 design.

B707-323C's operated by American Airlines were equipped with only 2 rather than 3 turbocompressors of most other -320B/C & -420 versions and also featured a different shaped # 4 engine pylon than aircraft operated by most other airlines.

B707-320C's were also produced as pure air freighters. These aircraft were stripped of all PAX furnishings and equipped with a reinforced maindeck featuring roller floor, guide rails, tie down points, 9G crash netting and capacity for 13 Type A containers or payloads of up to 91,390lbs.

Some pure freight aircraft were built completly devoid of cabin windows but most operators using B707-320C's for flexible PAX/freight and charter services opted to retain these. The versatility of B707-320C accelerated popularity of the B707 among airlines of the world. Production of this particular model surged ahead of the DC8 amassing to a total of 337 airframes.

During the 1980's many originally PAX configured B707-320C's were converted to pure freighters when operators embarked upon fleet replacement programs and began upgrading with more advanced/economic aircraft types. In many cases B707's were retained exclusively for cargo operations whilst others were sold to airlines of developing nations around the world or withdrawn from service completly and scrapped. By far the majority of B707-320C's remaining in service during the 1980's and 90's were Husk-Kitted in compliance with international noise regulations. All B707-320C's had a fuselage length of 152ft 11in, wingspan of 145ft 8.5in, and capacity for 147-189 PAX depending on aircraft/airline configuration ...later production B707-320C's were recertified for up to 219 PAX (competing with DC8-62 & -63) and featured an additional central rear fuselage located emergency exit on both port and starboard sides. These aircraft were powered by P&W JT3D-3, JT3D-3B, or JT3D-7 fanjet engines (depending on airline selection) rated at 17,000-19,000lb/st e/a, and had a MTOW of 333,600lb, and range of some 6,465nm depending on payload and reserves.

During the mid 1950's the USAF began evaluating suitability of civil B707's for military VIP/general transport service. This resulted in 3 B707-120 aircraft being delivered to the 1254th MAW based at Andrews AFB Maryland from May 4 1959 ...designated VC137-A. Each was configured with a forward cabin VIP lounge, midships located airborne HQ facilities, and rear cabin accomodation for up to 40 PAX. These aircraft eventually replaced the antiquated piston engined DC6 and CONSTELLATION based types which had previously serviced USAF/SAM roles. Although not specifically intended for presidential/government type charters, these aircraft were none-the-less occasionally engaged as official transports during prestigeous US government/state visits abroad. One such diplomatic tour to West Germany during August 1959 saw US president Dweight EISENHOWER become first of the federal jet Set.

All 3 USAF VC137-A's were originally powered by water/methanol injected P&W JT3C-6 turbojet engines when first delivered during 1959. These aircraft also featured the same structural and aerodynamic characteristics of original B707-120's. Each was upgraded with P&W TF33 fanjet engines, along with standard B707-120B tail extension and ventral fin modifications during 1963 ...redesignated VC137-B. The TF33 powerplant was a military version of the civil P&W JT3D series fanjet engine offering greater power, improved fuel economy, and considerably less noise. Under the CARTER administration of the late 1970's these aircraft were cosmetically redesignated C137-B. Although quickly superseded by higher performance B707-320B aircraft, all 3 USAF C137-B's remained in military/government operation until 1997 when they were finally withdrawn from service and replaced with more advanced and economic C32-A (B757-200) aircraft. A single C137-B aircraft has been preserved for permanant display at the Boeing Museum of Flight in Seattle.

2 longer ranging B707-320B aircraft were also eventually acquired by the USAF for SAM operations ...designated VC137-C. Deliveries of these aircraft commenced to the 89th MAW based at Andrews AFB from October 10 1962. Each was configured with forward cabin accomodation for staff and associated entourage, midships located airborne HQ with advanced communications fascilities, and a rear cabin de-luxe/presidential type suite. The first aircraft (# 72-6000) was built to early model B707-320B specifications with a rear fuselage ventral fin, and powered by military P&W TF33 fanjet series engines featuring small sucker doors on each engine inlet casing and early nose gear door design. Under the NIXON regime and during 1969 this particular aircraft was reconfigured internally and upgraded to B707-320B ADVANCED specifications ...the ventral fin was removed, and the aircraft re-engined with civil P&W JT3D fanjet engines. The 2nd VC137-C (# 72-7000) was built to B707-320B ADVANCED standard and delivered to the USAF during August 1972. These aircraft were maintained in a permanant state of readiness throughout their USAF service years. Both were used frequently by the US government for presidential/state visits abroad ...bearing the prestigeous "AIR FORCE ONE" call-sign whenever officially engaged with a US president aboard. VC137-C aircraft remained in USAF/AMC service as VIP/general transports until 1988 when they were replaced by larger, more modern, and higher performance VC24-A (B747-200) aircraft.

From February 1970 the RCAF took delivery of 5 B707-320C's ...designated CC-137. 3 of these aircraft were employed in VIP/general transport service roles until replaced with AIRBUS A310's during 1995. The remaining 2 aircraft were delivered as tankers with BEECH 1800 pods located below each wing tip and equipped short boom hose & drogue refuelling systems. These aircraft remained in service with the RCAF until 1997 when they were sold to the USAF for E8 JSTAR conversion.

During the early 1960's Boeing studied a variety of prospective future B707 developments. These ranged from stretched fuselage to double-decker configurations intended for high density domestic/trans-continental and intercontinental services (in response to DC8-61 & -63). Among such prospective designs was a swing-tail proposal promoting unimpaired fuselage/maindeck access and intended for both freight and miltary markets. None of these projects ever came to fruition due to the unavailability of suitable powerplants, limitations imposed by the basic B707 design, the lack of both civil and military support, and Boeing's ultimate decision to focus upon mass transportation and high logistics in the form of developing the worlds first long range wide-body jetliner ...the B747 JUMBO JET.

Rising fuel costs during the 1970's and more stringent noise regulations of the 1980's began to discriminate against B707, CV880, CV990, DC8 & VC10 aircraft generally. In attempt to resolve noise issues Boeing designed and tested a quiet engine nacelle during 1973 and intended specifically for P&W JT3D powered B707's only. Airline interest was negligeable and the entire project consequently abandoned. By the 1980's all civil operators were suddenly confronted by Stage 2, then even more imposing Stage 3 noise regulations of the 1990's. Need to either comply with FAA/ICAO noise regulations or retire otherwise perfectly airworthy B707 airframes forced independant studies into both Hush-Kitting and re-enginning with quieter, even more powerful, fuel efficient, and environmentally clean turbofan engines.

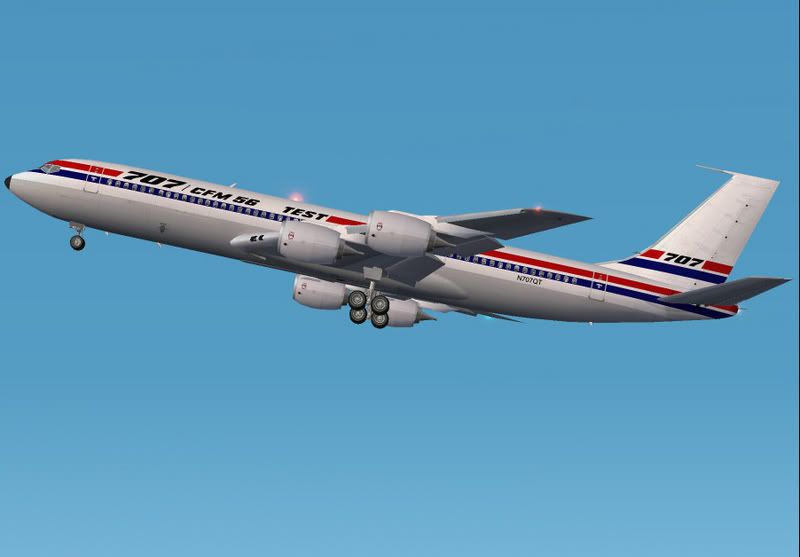

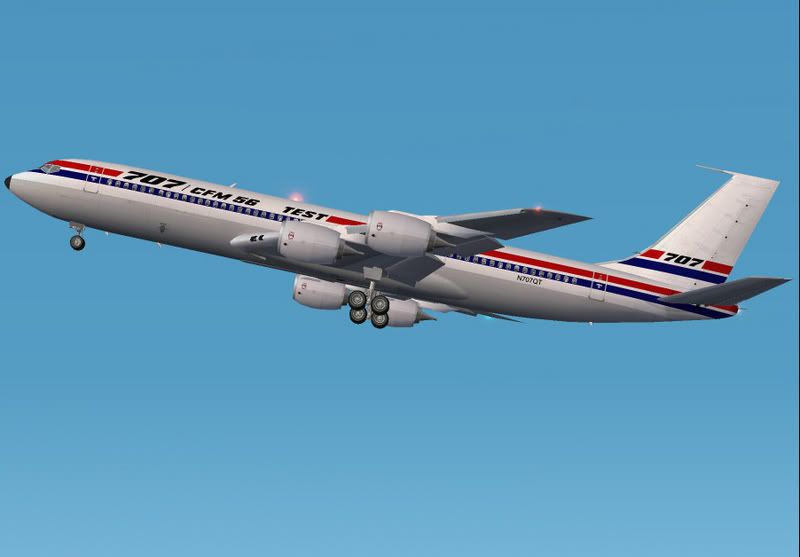

A single factory fresh B707-320C (N707QT) was re-engined with 4 CFM 56-1 turbofan engines rated at 22,000lbs/st e/a ...redesignated B707-700. This aircraft first flew on November 27 1979. It was used for flight testing and certification of the new CFM-56 turbofan, and to evaluate its potential as a replacement powerplant for P&W JT3D powered B707's. Despite significant performance improvements (17% more power. 25% greater fuel economy. 60% less noise) the huge expence of wing, landing gear, and fuselage modifications necessary to successfully impliment the new powerplant was considered excessive to any advantage ...more so considering B707's lower logistical/payload capabilities in comparason to much larger Super DC8's. By this time airlines around the world were also favoring new/more advanced twin engine aircraft technology (B757, B767, and other AIRBUS types) and were less enthusiastic about what most perceived as being little more than a revamped classic jetliner design. No other B707's were ever converted to CFM turbofan power. Beyond its brief CFM 56 test career N707QT was again re-engined and defaulted back to standard P&W JT3D fanjet powerplants and its original B707-320C designation. This particular aircraft was delivered to the Government of Morocco on March 10 1982. It was also the last civil B707 airframe produced by Boeing.

Despite CFM's lack of success with the civil B707 re-engining program, a significant number of early military C135 (type) aircraft have been upgraded with CFM turbofans since 1984.

Most of these aircraft remain in active service today within the USAF and other military forces around the world.

Late production military C135 (type) aircraft were built with CFM turbofans from 1987.

By the 1980´s all civil operators whom retained their B707´s were obliged to Hush-Kit (or retire) these aircraft in order to continue operating legally under new noise regulations. During the early 1990's Comtran International Inc; developed Q-707 nacelle/Hush-Kits, featuring a lengthened intake cowling and extended exaust tail pipe which reduced noise sufficiently to meet Stage 2 requirements. From 1996 Quiet Skies Inc; in conjunction with Burbank Aeronautical Corp2; further advanced this concept to produce Stage 3 compliant hush-kits which were publicly demonstrated by B707-3J6B N717QS at the 1998 Farnborough Air Show. Also developed and tested on this aircraft were 8ft.10in winglets which resulted in drag rduuction with a corresponding 7% improvement in overall fuel economy. More recently the Seven Q Seven Group (comprising of EADS-Dornier, Goodrich Aerospace, Nordham Group, Omega Air, and Pratt & Whitney) re-engined a single B707-320B with P&W JT8D-219 turbofans rated at 22,000lb/st e/a. This aircraft was redesignated B707-RE and first flew on August 21 2001. Flight testing revealed both a 22% improvement in overall fuel economy, reduced smoke emission, and noise rduction well within Stage 3 limitations. The P&W JT8D-219 turbofan engine has also been selected to replace ageing, noisey, dirty, and less fuel efficient P&W TF33 series fanjet engines (based on the original P&W JT3D fanjet engine series of the 1960´s) which still power much of the USAF JSTARS & AWACS inventory.

Although the last civil B707 was produced during 1979, the basic B707-320C airframe remained in production until 1991 as military E3 SENTRY/AWACS, and E6 MERCURY aircraft for the USAF.

Throughout the 1980's and 1990's retired ex airline B707's were also acquired by the USAF and other military forces around the world. Many of these aircraft were extensively modified for both aerial refuelling and electronic surveilance roles to operate under numerous type designations. Major partners involved in military B707/C135 (type) conversion/upgrade programs include Israel Aircraft Industries, Northrop Grumman, Omega Air, and Raetheon Systems. Ex civil B707's were also acquired by military services around the world and converted for SAM/VIP/general transport service, or used for spares recovery. Some of these aircraft have even occasionally been used to fulfill temporary leases with civil carriers to provide additional lift during peak traffic seasons.

Countries and world states (other than the USA and Canada) whom have operated B707 aircraft on their military/government service inventories include Abu-Dhabi, Angola, Argentina, Australia, Brasil, Chile, Colombia, Dubai, Egypt, Germany, India, Indonesia, Iran, Israel, Italy, Lybia, Morocco, Pakistan, Peru, Saudia Arabia, South Africa, Spain, Togo, Venezuela, Yugoslavia, and Zaire.

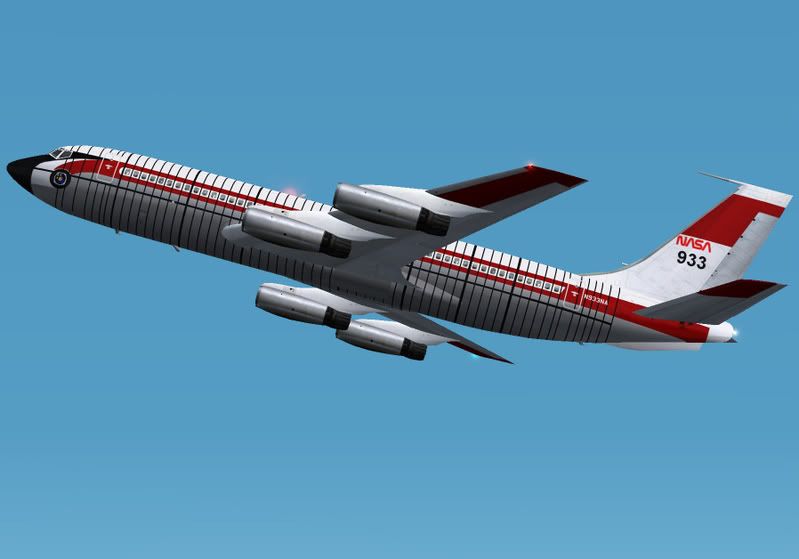

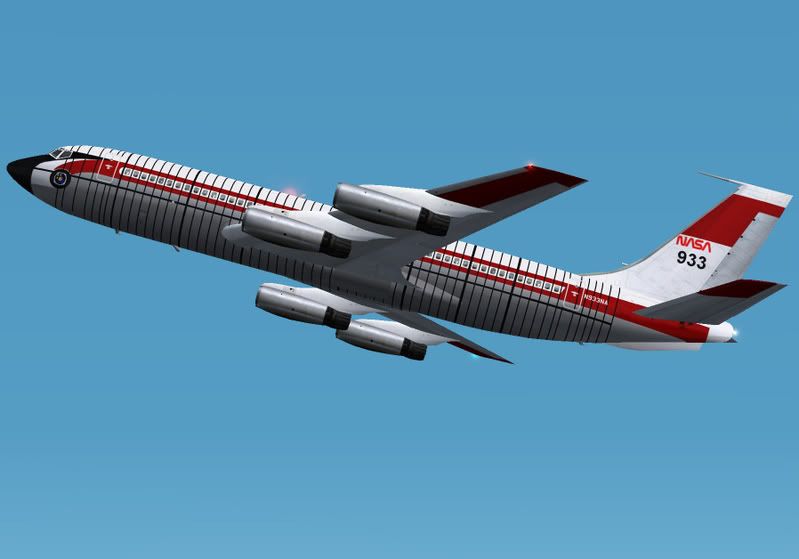

At least 2 B720 aircraft have also been deployed in military/government service roles. Between 1977 and 1980 the FAA operated a single B720-020 for flight safety analysis and general transport service. This particular aircraft was eventually sacrifised during a NASA experiment to determine effectivenes of AMK kerosene in a remotely controlled crash test at Edwards AFB California on December 1 1984. Throughout the 1970's the Taiwan Air Force operated an ex American Airlines B720-020B for VIP/general transport services. This particular aircraft was later also operated by Middle East Airlines. Upon withdrawal from service during 1995 it was converted to a restaurant and located at Journieh Lebanon.

Over 34 years the total production of B707/720 aircraft amounted to some 1,010 airframes ...exceeding DC8 production by almost double, and that of the Convair jetliners by more than 10 times. Some 820 C135 (type) airframes were also produced by Boeing in response to military contracts alone.

Very few B707's remain in commercial service today. Among those still active are a private B707-138B owned by world famous celebrity John TRAVOLTA (operated in 1960's QANTAS V-JET livery). A VIP configured B707-320B operated by Lowa Ltd, and B707-320C's in service with both Saha Air of Iran (originally produced as aerial refuellers for the Imperial Irnian Air Force), and BETA Cargo of Brasil.

Unlike a rare B707-138B recently acquired from the UK by the QANTAS Foundation Memorial Museum (displayed in the airlines original 1959 livery), few B707's have been preserved as permanant exibits forming various aircraft collections owned by transport museums around the world. Sadly these aircraft are today often worth more in scrap value than most are willing or can afford paying to preserve and exhibit them for public appreciation.

Prior to B367-80's first flight on July 15 1954 and advent of the civil jet age, Boeing was very much an unknown quantity and a less significant producer of commercial aircraft. The B707 levered Boeing to triumph, and the forefront of modern jetliner technology, as one of the greatest producers of civil aircraft today.

Mark CRANSTON

AKL/NZ

B707-320 & -420 became highly successful long range intercontinental jetliners but were quickly superseded by advent of P&W fanjet engine technology offering more power, better fuel economy, and greater environmental acceptability. These benefits promoted development of the definitive B707 series marketed as B707-320B & B707-320C (competing with DC8-50 & -62). These new versions retained the long B707-320/420 fuselage, and basic wing design ...though modified with low-drag curved tips which also increased overall wingspan by 3ft 3.5in. The B707-120B & B720-020B leading edge extension/wing glove was never incorporated into the wing design of these aircraft but flap systems were redesigned and varied slightly between both versions. B707-320B & -320C were capable of higher operating weights, longer range, and far superior performance than any of their type predecessors.

B707-320B first flew on January 31 1962 and was awarded FAA certification on May 31 1962. Deliveries commenced to Pan American from April 12 1962. All B707-320B's featured the standard extended tail. Very early production aircraft also retained the lower rear fuselage ventral fin, and were powered by original P&W fanjet series engines with small sucker doors located near the center of each engine inlet casing ...similar to those of B707-120B & B720-020B models and early type nose gear doors. Early B707-320B's aircraft were also equipped with half span slotted leading edge flaps and a revised trailing edge flap system featuring a unique Flap 17 detent.

Later production versions, and by far the majority of B707-320B aircraft built, were designated B707-320B ADVANCED models. These aircraft had slightly more powerful P&W fanjet series engines with larger sucker doors (further improving air-flow through each engine) relocated near the leading edge of each engine inlet casing and redesigned nose gear doors. B707-320B ADVANCED aircraft were also equipped with full span slotted leading edge flaps and a further redesigned trailing edge flap system featuring a standard Flap 14 detent. These modifications promoted corresponding performance improvements and slight MTOW increases. B707-320B ADVANCED aircraft also dispensed with the lower rear fuselage ventral fin. Some early prodution B707-320B's were later upgraded to ADVANCED aircraft standard.

A very small number of B707-320B's were produced with a forward fuselage maindeck cargo door but lacked reinforced flooring of the convertible B707-320C. These became reduced MTOW combi type aircraft intended for flexible or mixed PAX/freight operations ...designated B707-320B SCD. This version first flew on May 15 1964 and 13 months after first flight of B707-320C. Only 4 airframes were ever produced. All were delivered to Northwest Airlines.

American Airlines B707-323B ADVANCED aircraft were equipped with only 2 rather than 3 turbocompressors of most other -320B/C & -420 versions and featured a different shaped # 4 engine pylon. A total of 174 B707-320B airframes were produced by Boeing. The last of the type being delivered to BOAC on April 17 1971. During the 1980's a small number of B707-320B's were converted to pure freighters. Most of these aircraft were eventually Husk-Kitted to meet Stage 2 & 3 FAA/ICAO noise regulations of the 1980's and 90's. All B707-320B's had a fuselage length of 152ft 11in, wingspan of 145ft 8.5in, and capacity for 121-141 PAX depending on aircraft/airline configuration. These aircraft were powered by P&W JT3D-1, JT3D-3, or JT3D-3B fanjet engines (depending on airline selection) rated at 17,000-18,000lb/st e/a, and had a MTOW of 331,000lb ...later increased to 335,000lb, and range of some 5,250nm depending on payload and reserves.

Further enhancement of the basic B707-320B resulted in the ultimate B707 aircraft ...designated B707-320C. Although visually identical to the preceeding B707-320B ADVANCED this version was developed as a longer ranging and higher MTOW convertible aircraft for flexible or mixed PAX/freight operations (competing with both DC8-50F & -62CF/F). The B707-320C was equipped with an 11ft 2in X 7ft 7in port side forward fuselage maindeck cargo door, in addition to standard underfloor baggage/freight hatches located on the lower starboard fuselage, and had a strengthened undercarriage for higher operating weights. B707-320C first flew on February 11 1963 and was awarded FAA certification on April 30 1963. Deliveries commenced to Pan American from May 2 1963. All were delivered with the standard extended tail. The lower rear fuselage ventral fin having become completly redundant from the B707 design.

B707-323C's operated by American Airlines were equipped with only 2 rather than 3 turbocompressors of most other -320B/C & -420 versions and also featured a different shaped # 4 engine pylon than aircraft operated by most other airlines.

B707-320C's were also produced as pure air freighters. These aircraft were stripped of all PAX furnishings and equipped with a reinforced maindeck featuring roller floor, guide rails, tie down points, 9G crash netting and capacity for 13 Type A containers or payloads of up to 91,390lbs.

Some pure freight aircraft were built completly devoid of cabin windows but most operators using B707-320C's for flexible PAX/freight and charter services opted to retain these. The versatility of B707-320C accelerated popularity of the B707 among airlines of the world. Production of this particular model surged ahead of the DC8 amassing to a total of 337 airframes.

During the 1980's many originally PAX configured B707-320C's were converted to pure freighters when operators embarked upon fleet replacement programs and began upgrading with more advanced/economic aircraft types. In many cases B707's were retained exclusively for cargo operations whilst others were sold to airlines of developing nations around the world or withdrawn from service completly and scrapped. By far the majority of B707-320C's remaining in service during the 1980's and 90's were Husk-Kitted in compliance with international noise regulations. All B707-320C's had a fuselage length of 152ft 11in, wingspan of 145ft 8.5in, and capacity for 147-189 PAX depending on aircraft/airline configuration ...later production B707-320C's were recertified for up to 219 PAX (competing with DC8-62 & -63) and featured an additional central rear fuselage located emergency exit on both port and starboard sides. These aircraft were powered by P&W JT3D-3, JT3D-3B, or JT3D-7 fanjet engines (depending on airline selection) rated at 17,000-19,000lb/st e/a, and had a MTOW of 333,600lb, and range of some 6,465nm depending on payload and reserves.

During the mid 1950's the USAF began evaluating suitability of civil B707's for military VIP/general transport service. This resulted in 3 B707-120 aircraft being delivered to the 1254th MAW based at Andrews AFB Maryland from May 4 1959 ...designated VC137-A. Each was configured with a forward cabin VIP lounge, midships located airborne HQ facilities, and rear cabin accomodation for up to 40 PAX. These aircraft eventually replaced the antiquated piston engined DC6 and CONSTELLATION based types which had previously serviced USAF/SAM roles. Although not specifically intended for presidential/government type charters, these aircraft were none-the-less occasionally engaged as official transports during prestigeous US government/state visits abroad. One such diplomatic tour to West Germany during August 1959 saw US president Dweight EISENHOWER become first of the federal jet Set.

All 3 USAF VC137-A's were originally powered by water/methanol injected P&W JT3C-6 turbojet engines when first delivered during 1959. These aircraft also featured the same structural and aerodynamic characteristics of original B707-120's. Each was upgraded with P&W TF33 fanjet engines, along with standard B707-120B tail extension and ventral fin modifications during 1963 ...redesignated VC137-B. The TF33 powerplant was a military version of the civil P&W JT3D series fanjet engine offering greater power, improved fuel economy, and considerably less noise. Under the CARTER administration of the late 1970's these aircraft were cosmetically redesignated C137-B. Although quickly superseded by higher performance B707-320B aircraft, all 3 USAF C137-B's remained in military/government operation until 1997 when they were finally withdrawn from service and replaced with more advanced and economic C32-A (B757-200) aircraft. A single C137-B aircraft has been preserved for permanant display at the Boeing Museum of Flight in Seattle.

2 longer ranging B707-320B aircraft were also eventually acquired by the USAF for SAM operations ...designated VC137-C. Deliveries of these aircraft commenced to the 89th MAW based at Andrews AFB from October 10 1962. Each was configured with forward cabin accomodation for staff and associated entourage, midships located airborne HQ with advanced communications fascilities, and a rear cabin de-luxe/presidential type suite. The first aircraft (# 72-6000) was built to early model B707-320B specifications with a rear fuselage ventral fin, and powered by military P&W TF33 fanjet series engines featuring small sucker doors on each engine inlet casing and early nose gear door design. Under the NIXON regime and during 1969 this particular aircraft was reconfigured internally and upgraded to B707-320B ADVANCED specifications ...the ventral fin was removed, and the aircraft re-engined with civil P&W JT3D fanjet engines. The 2nd VC137-C (# 72-7000) was built to B707-320B ADVANCED standard and delivered to the USAF during August 1972. These aircraft were maintained in a permanant state of readiness throughout their USAF service years. Both were used frequently by the US government for presidential/state visits abroad ...bearing the prestigeous "AIR FORCE ONE" call-sign whenever officially engaged with a US president aboard. VC137-C aircraft remained in USAF/AMC service as VIP/general transports until 1988 when they were replaced by larger, more modern, and higher performance VC24-A (B747-200) aircraft.

From February 1970 the RCAF took delivery of 5 B707-320C's ...designated CC-137. 3 of these aircraft were employed in VIP/general transport service roles until replaced with AIRBUS A310's during 1995. The remaining 2 aircraft were delivered as tankers with BEECH 1800 pods located below each wing tip and equipped short boom hose & drogue refuelling systems. These aircraft remained in service with the RCAF until 1997 when they were sold to the USAF for E8 JSTAR conversion.

During the early 1960's Boeing studied a variety of prospective future B707 developments. These ranged from stretched fuselage to double-decker configurations intended for high density domestic/trans-continental and intercontinental services (in response to DC8-61 & -63). Among such prospective designs was a swing-tail proposal promoting unimpaired fuselage/maindeck access and intended for both freight and miltary markets. None of these projects ever came to fruition due to the unavailability of suitable powerplants, limitations imposed by the basic B707 design, the lack of both civil and military support, and Boeing's ultimate decision to focus upon mass transportation and high logistics in the form of developing the worlds first long range wide-body jetliner ...the B747 JUMBO JET.

Rising fuel costs during the 1970's and more stringent noise regulations of the 1980's began to discriminate against B707, CV880, CV990, DC8 & VC10 aircraft generally. In attempt to resolve noise issues Boeing designed and tested a quiet engine nacelle during 1973 and intended specifically for P&W JT3D powered B707's only. Airline interest was negligeable and the entire project consequently abandoned. By the 1980's all civil operators were suddenly confronted by Stage 2, then even more imposing Stage 3 noise regulations of the 1990's. Need to either comply with FAA/ICAO noise regulations or retire otherwise perfectly airworthy B707 airframes forced independant studies into both Hush-Kitting and re-enginning with quieter, even more powerful, fuel efficient, and environmentally clean turbofan engines.

A single factory fresh B707-320C (N707QT) was re-engined with 4 CFM 56-1 turbofan engines rated at 22,000lbs/st e/a ...redesignated B707-700. This aircraft first flew on November 27 1979. It was used for flight testing and certification of the new CFM-56 turbofan, and to evaluate its potential as a replacement powerplant for P&W JT3D powered B707's. Despite significant performance improvements (17% more power. 25% greater fuel economy. 60% less noise) the huge expence of wing, landing gear, and fuselage modifications necessary to successfully impliment the new powerplant was considered excessive to any advantage ...more so considering B707's lower logistical/payload capabilities in comparason to much larger Super DC8's. By this time airlines around the world were also favoring new/more advanced twin engine aircraft technology (B757, B767, and other AIRBUS types) and were less enthusiastic about what most perceived as being little more than a revamped classic jetliner design. No other B707's were ever converted to CFM turbofan power. Beyond its brief CFM 56 test career N707QT was again re-engined and defaulted back to standard P&W JT3D fanjet powerplants and its original B707-320C designation. This particular aircraft was delivered to the Government of Morocco on March 10 1982. It was also the last civil B707 airframe produced by Boeing.

Despite CFM's lack of success with the civil B707 re-engining program, a significant number of early military C135 (type) aircraft have been upgraded with CFM turbofans since 1984.

Most of these aircraft remain in active service today within the USAF and other military forces around the world.

Late production military C135 (type) aircraft were built with CFM turbofans from 1987.

By the 1980´s all civil operators whom retained their B707´s were obliged to Hush-Kit (or retire) these aircraft in order to continue operating legally under new noise regulations. During the early 1990's Comtran International Inc; developed Q-707 nacelle/Hush-Kits, featuring a lengthened intake cowling and extended exaust tail pipe which reduced noise sufficiently to meet Stage 2 requirements. From 1996 Quiet Skies Inc; in conjunction with Burbank Aeronautical Corp2; further advanced this concept to produce Stage 3 compliant hush-kits which were publicly demonstrated by B707-3J6B N717QS at the 1998 Farnborough Air Show. Also developed and tested on this aircraft were 8ft.10in winglets which resulted in drag rduuction with a corresponding 7% improvement in overall fuel economy. More recently the Seven Q Seven Group (comprising of EADS-Dornier, Goodrich Aerospace, Nordham Group, Omega Air, and Pratt & Whitney) re-engined a single B707-320B with P&W JT8D-219 turbofans rated at 22,000lb/st e/a. This aircraft was redesignated B707-RE and first flew on August 21 2001. Flight testing revealed both a 22% improvement in overall fuel economy, reduced smoke emission, and noise rduction well within Stage 3 limitations. The P&W JT8D-219 turbofan engine has also been selected to replace ageing, noisey, dirty, and less fuel efficient P&W TF33 series fanjet engines (based on the original P&W JT3D fanjet engine series of the 1960´s) which still power much of the USAF JSTARS & AWACS inventory.

Although the last civil B707 was produced during 1979, the basic B707-320C airframe remained in production until 1991 as military E3 SENTRY/AWACS, and E6 MERCURY aircraft for the USAF.

Throughout the 1980's and 1990's retired ex airline B707's were also acquired by the USAF and other military forces around the world. Many of these aircraft were extensively modified for both aerial refuelling and electronic surveilance roles to operate under numerous type designations. Major partners involved in military B707/C135 (type) conversion/upgrade programs include Israel Aircraft Industries, Northrop Grumman, Omega Air, and Raetheon Systems. Ex civil B707's were also acquired by military services around the world and converted for SAM/VIP/general transport service, or used for spares recovery. Some of these aircraft have even occasionally been used to fulfill temporary leases with civil carriers to provide additional lift during peak traffic seasons.

Countries and world states (other than the USA and Canada) whom have operated B707 aircraft on their military/government service inventories include Abu-Dhabi, Angola, Argentina, Australia, Brasil, Chile, Colombia, Dubai, Egypt, Germany, India, Indonesia, Iran, Israel, Italy, Lybia, Morocco, Pakistan, Peru, Saudia Arabia, South Africa, Spain, Togo, Venezuela, Yugoslavia, and Zaire.

At least 2 B720 aircraft have also been deployed in military/government service roles. Between 1977 and 1980 the FAA operated a single B720-020 for flight safety analysis and general transport service. This particular aircraft was eventually sacrifised during a NASA experiment to determine effectivenes of AMK kerosene in a remotely controlled crash test at Edwards AFB California on December 1 1984. Throughout the 1970's the Taiwan Air Force operated an ex American Airlines B720-020B for VIP/general transport services. This particular aircraft was later also operated by Middle East Airlines. Upon withdrawal from service during 1995 it was converted to a restaurant and located at Journieh Lebanon.

Over 34 years the total production of B707/720 aircraft amounted to some 1,010 airframes ...exceeding DC8 production by almost double, and that of the Convair jetliners by more than 10 times. Some 820 C135 (type) airframes were also produced by Boeing in response to military contracts alone.

Very few B707's remain in commercial service today. Among those still active are a private B707-138B owned by world famous celebrity John TRAVOLTA (operated in 1960's QANTAS V-JET livery). A VIP configured B707-320B operated by Lowa Ltd, and B707-320C's in service with both Saha Air of Iran (originally produced as aerial refuellers for the Imperial Irnian Air Force), and BETA Cargo of Brasil.

Unlike a rare B707-138B recently acquired from the UK by the QANTAS Foundation Memorial Museum (displayed in the airlines original 1959 livery), few B707's have been preserved as permanant exibits forming various aircraft collections owned by transport museums around the world. Sadly these aircraft are today often worth more in scrap value than most are willing or can afford paying to preserve and exhibit them for public appreciation.

Prior to B367-80's first flight on July 15 1954 and advent of the civil jet age, Boeing was very much an unknown quantity and a less significant producer of commercial aircraft. The B707 levered Boeing to triumph, and the forefront of modern jetliner technology, as one of the greatest producers of civil aircraft today.

Mark CRANSTON

AKL/NZ

;D

;D